Métis Vela UniPD Update

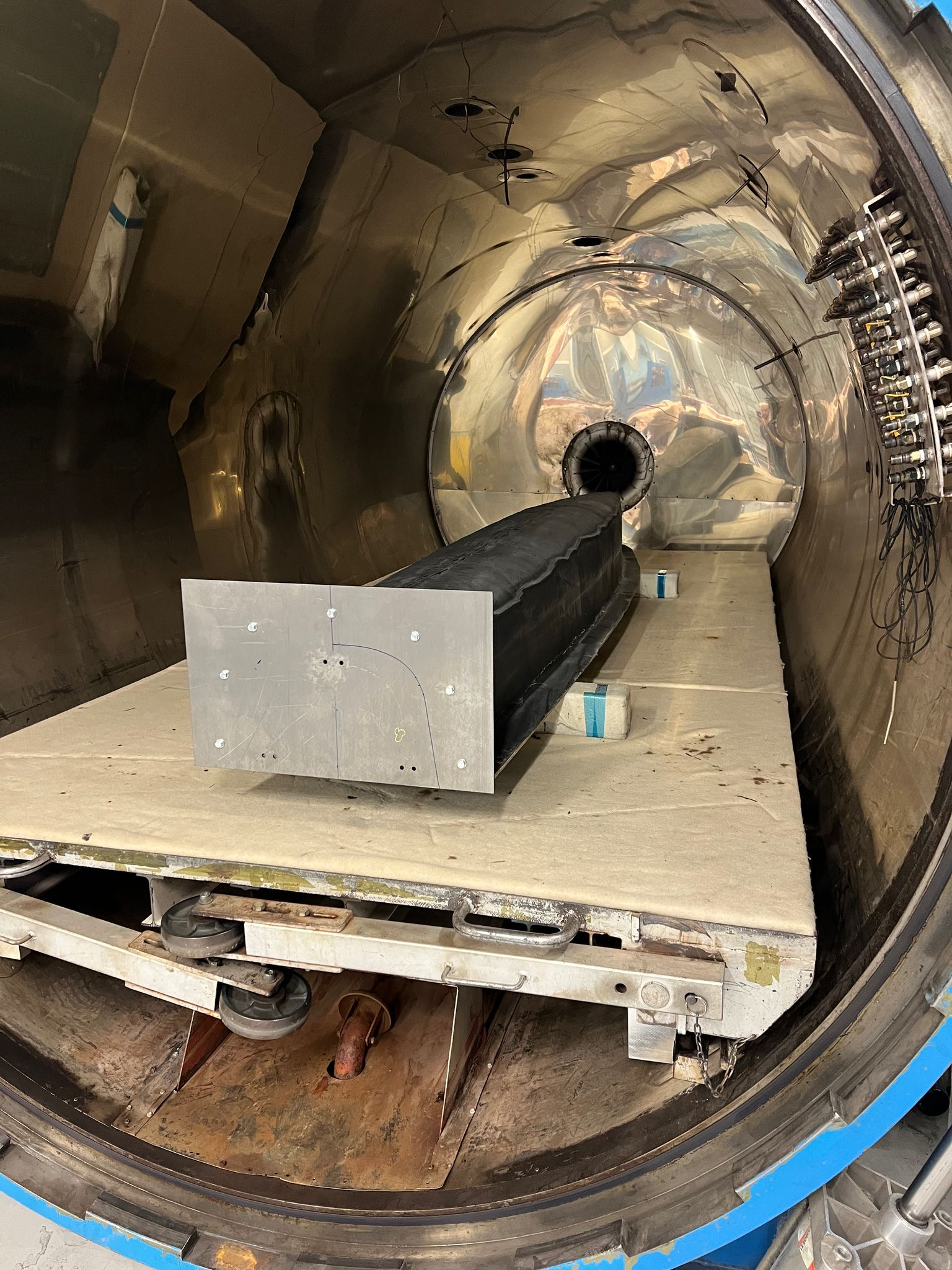

The Métis Vela UniPD team is entering a pivotal phase in the preparation for the Foiling SuMoth Challenge 2025, moving steadily from planning to execution. We have recently completed the construction of the wooden master, the female hull mould, and the forestay support mould, employing a mix of infusion techniques, hand lamination, and autoclave processes.

With the hull mould post-curing process now complete, our attention has turned to perfecting the final details in preparation for hand laminating the hull. I

n parallel, the wingbars and foil moulds are under construction in close collaboration with two of our key technical sponsors. Every component is being carefully crafted to meet our rigorous standards of performance, innovation, and sustainability.

Design Approach and Sustainable Choices

Sustainability has been a guiding principle in every step of our build. For the foil moulds, we’ve repurposed spare PU blocks donated by other student teams within the University of Padua — significantly reducing our environmental impact, since PU production typically involves high energy consumption.

Sustainability has been a guiding principle in every step of our build. For the foil moulds, we’ve repurposed spare PU blocks donated by other student teams within the University of Padua — significantly reducing our environmental impact, since PU production typically involves high energy consumption.

Additionally, we’re making extensive use of leftover carbon fiber and resin from earlier tests, minimizing waste without compromising the performance of the final structure. These choices reflect our commitment to responsible engineering, ensuring that we develop a fast, safe, and efficient craft with a minimized environmental footprint.

Achieved Milestones

This semester has seen major progress, both in terms of production and team visibility.

We’ve secured new partnerships with technical and financial sponsors, strengthening both our capabilities and our outreach. Our technical sponsors provide materials and manufacturing services, while financial sponsors have backed our project because they believe in its vision and educational impact.

We’ve also had the honor of being invited to present our project at a corporate event hosted by one of our sponsors, introducing our work to employees and their families. Looking ahead, we’re preparing to exhibit our boat at the Salone Nautico di Venezia, bringing our innovation to the wider public and the professional sailing industry.

In early April, we also took part in a university-wide exhibition, bringing together all student-led teams across disciplines — from motorcycles to satellites. It was a valuable opportunity for networking, idea exchange, and recruiting new talent.

Meanwhile, on Lake Garda, our crew began training sessions in Brenzone, using past boats to identify technical challenges, practice teamwork, and gather insights for further design refinements.

Technically, we’ve pushed our limits with new manufacturing techniques like VARTM, and we’ve also explored the performance limits of oven-cured flax fibers, continuously refining our understanding and skills.

Final Steps Before the Challenge

As the competition draws closer, we are focused on completing several key stages. Next, we’ll move forward with hand lamination of the hull using a mix of flax and carbon prepregs, paired with PET and aluminum honeycomb cores. This will happen in two steps:

- A first layer, followed by autoclave curing.

- A second layer, which will integrate the core materials and resin films.

Component testing remains ahead, but we have successfully validated our FEM and CFD models, ensuring the soundness of our design under performance simulations.

Currently, we are working closely with the electronics department to develop a real-time Volume of Fluid (VOF) system — a major leap that could give us valuable data during water testing and competition runs.

With enthusiasm high and every subteam working in sync, Métis Vela UniPD is on track to deliver a competitive, sustainable, and innovative entry for the Foiling SuMoth Challenge 2025. We’re proud of the road we’ve traveled and look forward to bringing our vision to life on the water.